The Desco range of cap and closure printers is designed to produce precise register and superb print quality at speeds of up to 4000 parts per minute and in up to 6 colors. Options are available for both flatbed and for rotary parts handling to suit specific production requirements.

The Desco range of cap and closure printers is designed to produce precise register and superb print quality at speeds of up to 4000 parts per minute and in up to 6 colors. Options are available for both flatbed and for rotary parts handling to suit specific production requirements.

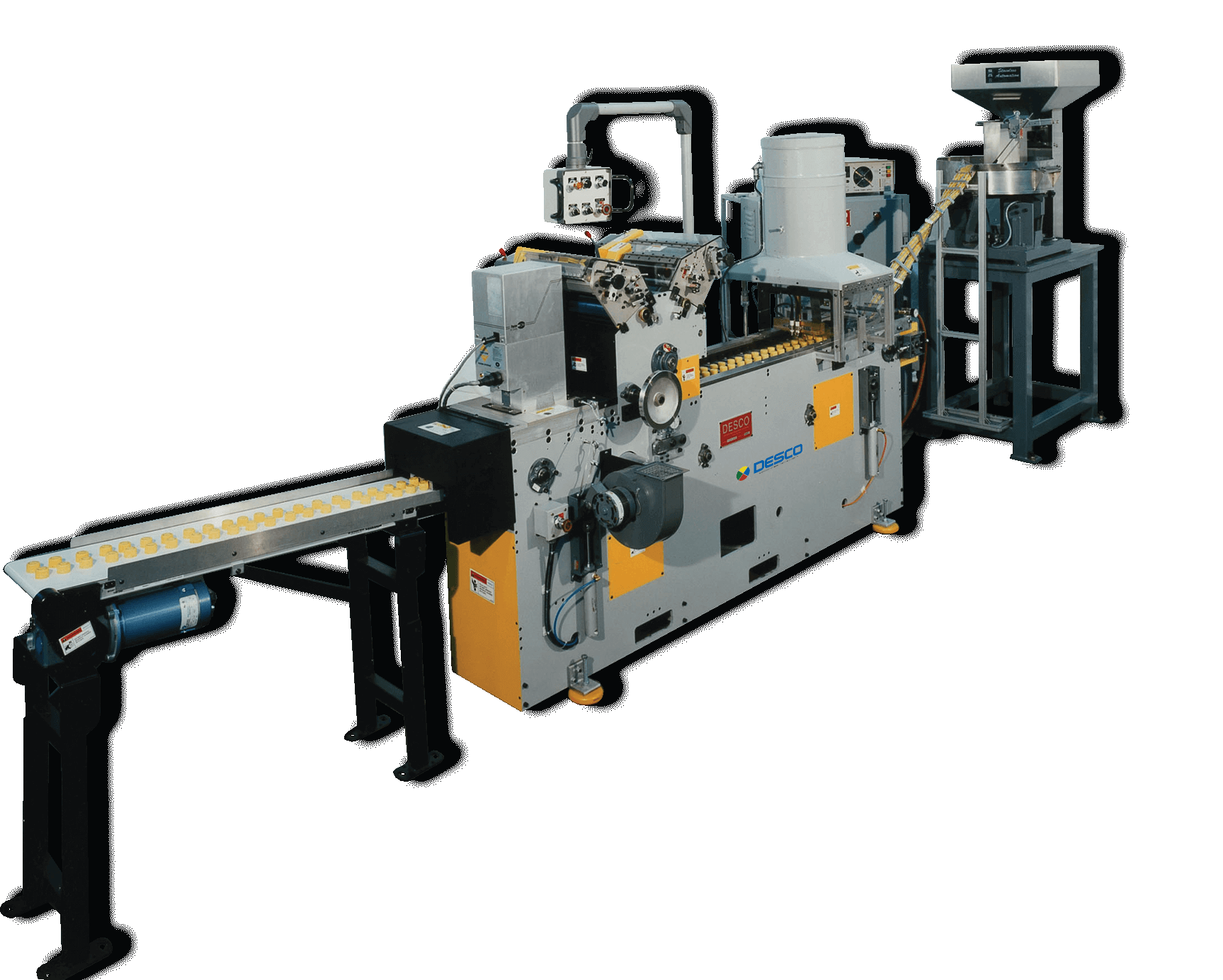

DRCP-4 Four Color Rotary

DRCP-4 - Four Color Rotary Cap Printer

Benefits

- Machine can be provided with up to 4 colors

- Totally automatic and capable of orienting, feeding, pre-treat, printing, UV drying, counting and boxing closures

- Welded steel construction

- Ink is cured while closure is still on platen

- Perfect register printing (gear to gear drive system)

- Running registration — radial and lateral adjustment can be made while press is operating

- Anti-backlash gearing throughout

- Swing-away roll section for access to plate cylinder

- Variable speed motor driven ink fountains

![Desco DRCP4 cap printer]() Accessories & Options

Accessories & Options

- Pre-feed systems

- Flame or Corona treat systems

- Vacuum destaticizers

- Automatic closure inspection system

- Counting and boxing

The most effective combination of printer and accessories for your application can only be determined by analysis of your specific closure requirements. Based on our global experience of many field installations, we welcome the opportunity to make an analysis and forward our recommendation to you.

DCP-4 Four Color

DCP-4 - Four Color Cap Printer

Benefits

- Perfect register printing

- Solid state DC variable speed drive

- Four color heads with removable color heads or swing-away color heads for easy access to plate cylinders

- Over-ride clutch protection of machine

- Convenient, positive pressure and ink flow controls

- Adjustable speed ink fountain roll

- Solid construction

- ultraviolet curing of ink while closure is still on platen

Accessories & Options

- Completely automated systems available

- Inspection conveyors

- Turntable/closure counters

- Box shakers

- Indexing full box conveyors

- Sorters

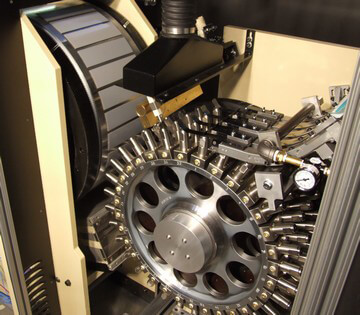

DRCP Rotary Printer

DRCP - Rotary Closure Printer Dual Blanket Cylinders

Benefits

- Two colors can be printed on the closure at the first blanket cylinder. After the first two colors are UV cured an additional two colors can be printed on the closure at the second blanket cylinder.

- Totally automatic and capable of orienting, feeding, pre-treat, printing, UV drying, counting and boxing closures

- Welded steel construction

- Ink is cured while closure is still on platen

- Perfect register printing (gear to gear drive system)

- Running registration — radial and lateral adjustment can be made while press is operating

- Anti-backlash gearing throughout

- Swing-away roll section for access to plate cylinder

- Variable speed motor driven ink fountains

![DRCP Rotary 2 + 2 Color Cap Printer schematic]() Accessories & Options

Accessories & Options

- Pre-feed systems

- Flame or Corona treat systems

- Vacuum destaticizers

- Automatic closure inspection system

- Counting and boxing

The most effective combination of printer and accessories for your application can only be determined by analysis of your specific closure requirements. Based on our global experience of many field installations, we welcome the opportunity to make an analysis and forward our recommendation to you.

DCP-3 Three Color

DCP-3 - Three Color Cap Printer

Benefits

- Perfect register printing

- Solid state DC variable speed drive

- Three color heads with removable color heads or swing-away color heads for easy access to plate cylinders

- Over-ride clutch protection of machine

- Convenient, positive pressure and ink flow controls

- Adjustable speed ink fountain roll

- Solid construction

- ultraviolet curing of ink while closure is still on platen

Accessories & Options

- Completely automated systems available

- Inspection conveyors

- Turntable/closure counters

- Box shakers

- Indexing full box conveyors

- Sorters

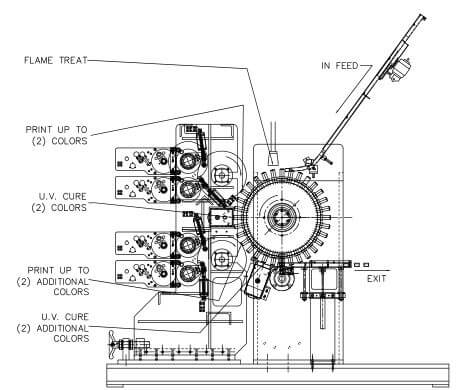

DCP-SCHT 2+4 Color

DCP-SCHT - 2 plus 4 Color Cap Printer

Benefits

- Capable of two base colors on closure at first tower

- Second tower applies up to four colors over base colors

- Totally automatic and capable of orienting, feeding, pre-treating, printing, drying, counting and boxing closures

- Welded steel construction

- Ink is cured while closure is still on platen

- U.V. curing unit after each tower

- Perfect registered printing

- Micro printing pressure adjustments throughout machine

- All controls on operator side

- Swing-away color head roller sections

- Existing DESCO printing plates can be used on the DCP-SCHT

- All functions of the system are monitored on display panel

- Automatic chain lubrication system

- Low cost of printing — no special inks, plates or proprietary equipment needed

Accessories & Options

- Pre-feed systems

- Flame or corona pre-treat

- Vacuum destaticizers

- Closure orientation

- Automatic de-gators

- Automatic closure inspection system

- Closure counting and boxing

- Printer can be integrated with the DESCO Under The Cap Printing System

DHLP Highlighting Printer

DHLP - Highlighting Printer

Benefits

- DESCO can supply a complete system capable of orienting, feeding, pre-treat, print and UV drying

- Flame treater section with exhaust hood

- Closures are conveyed on stainless steel belt

- Highlighter roll section mounted on micro-slide

- Roll section has dual inked rotating rolls that transfer ink to the raised areas on the closures

- Ultraviolet curing of inks

- Full electronic control through PLC

Accessories & Options

Accessories & Options Accessories & Options

Accessories & Options